Water Fed Tile Cutter

Getting to Know Water Fed Tile Cutter

If you're in the business of laying tile for showers, backsplashes, and other installations, you know how challenging it can be to cut your tiles perfectly. To assist with this process, many contractors rely on water fed tile cutters, which make precision cuts and help to reduce messes in the process. Here's everything you need to know about water fed tile cutters.

Understanding Water Fed Tile Cutters

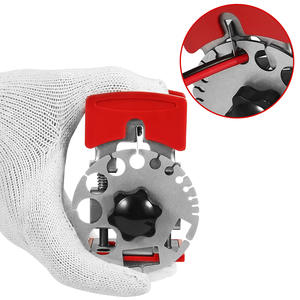

A water fed tile cutter is a specialized tool that operates via a water-cooled diamond blade. This blade rotates at high speeds and is specifically designed to make cuts through various types of tile—including porcelain, glass, and ceramic—with ease. By using a continuous flow of water, these machines can make precise cuts without damaging the tiles, which is ideal for creating intricate cuts and designs.

How Water Fed Tile Cutters Work

These cutters are designed to be easy to operate, even for novice tile setters. The tool is equipped with a water reservoir that pumps water over the blade as it cuts the tile. The end result is a clean, precise cut that helps to minimize the amount of debris and dust that is typically created with traditional tile cutting methods.The Benefits of Using a Water Fed Tile Cutter

There are a number of benefits associated with using a water fed tile cutter. First and foremost, these cutters can help to increase overall efficiency and speed when working on tile cutting projects. They can also help to reduce the risk of tile breakage or chipping during the cutting process, which in turn can help to minimize materials waste and additional labor costs. Additionally, water fed tile cutters can help to reduce messes and dust that are created during the cutting process, which can be especially useful for indoor projects where dust may need to be kept to a minimum.Types of Water Fed Tile Cutters

There are many different types of water fed tile cutters available on the market today. Some are designed for small, DIY tile cutting projects while others are intended for more commercial use. Some cutters come with additional features like laser guides for added precision, while others can be connected to a wet vacuum to further reduce dust and debris during the cutting process.

There are many different types of water fed tile cutters available on the market today. Some are designed for small, DIY tile cutting projects while others are intended for more commercial use. Some cutters come with additional features like laser guides for added precision, while others can be connected to a wet vacuum to further reduce dust and debris during the cutting process.

Things to Consider When Using Water Fed Tile Cutters

While these tools are generally safe and easy to use, it's still important to take certain precautions when using them. Always wear protective eye and ear gear when operating a water fed tile cutter and avoid wearing loose clothing or jewelry that could get caught in the blade. Additionally, be sure to follow all manufacturer instructions closely and work in a well-ventilated area to avoid inhaling any dust or debris during the cutting process.The Bottom Line

Overall, a water fed tile cutter can be an incredibly useful tool for anyone working with tile installations. By providing precise cuts and minimizing messes and debris, these cutters can help to streamline your work process and result in a more professional and polished final product. Whether you're a seasoned pro or just starting out, a water fed tile cutter is an investment in your tile laying work that is sure to pay off over time.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]