Water Cutting Stone

Water Cutting Stone: The Magic of Abrasive Waterjets

Abrasive waterjet is a precision cutting process that utilizes a combination of high-pressure water and abrasive particles to erode and cut through the material. The force of the water stream, traveling at speeds up to 900 meters per second, generates enough energy to cut through even the hardest materials. The abrasive particles, usually made of garnet, add an extra cutting power to the water stream and accelerate the erosion process, resulting in a precise and smooth cut.

Abrasive waterjet is a precision cutting process that utilizes a combination of high-pressure water and abrasive particles to erode and cut through the material. The force of the water stream, traveling at speeds up to 900 meters per second, generates enough energy to cut through even the hardest materials. The abrasive particles, usually made of garnet, add an extra cutting power to the water stream and accelerate the erosion process, resulting in a precise and smooth cut.

Water cutting offers several advantages over traditional stone-cutting methods. One of the most significant advantages of water cutting is that it is a cold cutting process, meaning that it doesn't generate heat, which can cause structural changes in the material. Waterjets can also cut intricate shapes and curves with high precision, which is difficult to achieve with other methods.

Another crucial advantage of water cutting is that it produces little to no waste material during the cutting process, making it environmentally friendly. Water cutting is also versatile, as it can cut through a variety of materials with different thicknesses and shapes.

Water cutting offers several advantages over traditional stone-cutting methods. One of the most significant advantages of water cutting is that it is a cold cutting process, meaning that it doesn't generate heat, which can cause structural changes in the material. Waterjets can also cut intricate shapes and curves with high precision, which is difficult to achieve with other methods.

Another crucial advantage of water cutting is that it produces little to no waste material during the cutting process, making it environmentally friendly. Water cutting is also versatile, as it can cut through a variety of materials with different thicknesses and shapes.

Introduction:

Water, considered as one of the most essential elements for survival, can also be a powerful tool to cut through the hardest materials on Earth. This is where the concept of abrasive waterjets comes into play. Abrasive waterjet machining is a process that uses high-pressure water, mixed with abrasive particles, to cut through a variety of materials, including stone.

The Science of Abrasive Waterjets:

Abrasive waterjet is a precision cutting process that utilizes a combination of high-pressure water and abrasive particles to erode and cut through the material. The force of the water stream, traveling at speeds up to 900 meters per second, generates enough energy to cut through even the hardest materials. The abrasive particles, usually made of garnet, add an extra cutting power to the water stream and accelerate the erosion process, resulting in a precise and smooth cut.

Abrasive waterjet is a precision cutting process that utilizes a combination of high-pressure water and abrasive particles to erode and cut through the material. The force of the water stream, traveling at speeds up to 900 meters per second, generates enough energy to cut through even the hardest materials. The abrasive particles, usually made of garnet, add an extra cutting power to the water stream and accelerate the erosion process, resulting in a precise and smooth cut.

The Advantages of Water Cutting Stone:

Water cutting offers several advantages over traditional stone-cutting methods. One of the most significant advantages of water cutting is that it is a cold cutting process, meaning that it doesn't generate heat, which can cause structural changes in the material. Waterjets can also cut intricate shapes and curves with high precision, which is difficult to achieve with other methods.

Another crucial advantage of water cutting is that it produces little to no waste material during the cutting process, making it environmentally friendly. Water cutting is also versatile, as it can cut through a variety of materials with different thicknesses and shapes.

Water cutting offers several advantages over traditional stone-cutting methods. One of the most significant advantages of water cutting is that it is a cold cutting process, meaning that it doesn't generate heat, which can cause structural changes in the material. Waterjets can also cut intricate shapes and curves with high precision, which is difficult to achieve with other methods.

Another crucial advantage of water cutting is that it produces little to no waste material during the cutting process, making it environmentally friendly. Water cutting is also versatile, as it can cut through a variety of materials with different thicknesses and shapes.

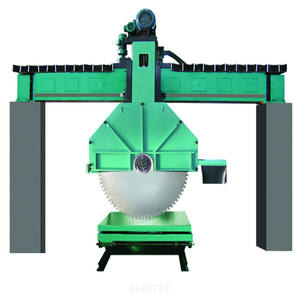

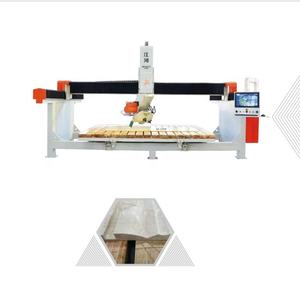

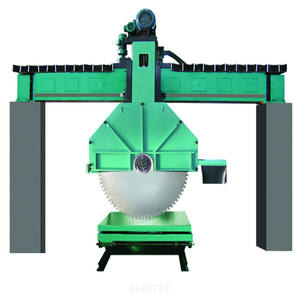

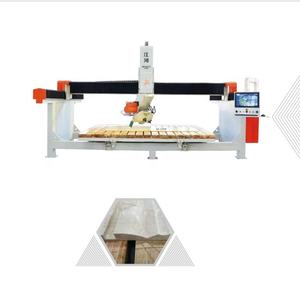

Applications of Water Cutting in Stone Industry:

Waterjet cutting has revolutionized the way the stone industry operates. With the ability to cut intricate designs in stone surfaces, such as marble and granite, it has brought a new level of creativity and precision to the industry. Water cutting is particularly useful in producing drainage channels in bathroom and kitchen countertops, carving intricate designs on fireplace surrounds, and producing sculptures and artwork.The Importance of Choosing a Professional Waterjet Cutting Service:

Water cutting stone requires specialized equipment and expertise. Choosing a professional waterjet cutting service is crucial for achieving the desired result. The service provider should have state-of-the-art equipment and a team of experienced professionals who can guarantee the precision and quality of the cut. A professional water cutting service can also provide customized solutions and advice on the best methods for cutting a particular stone material.The Future of Water Cutting in Stone Industry:

Water cutting is an ever-evolving technology with new innovations and advancements continuously being developed. Some of the latest developments include the use of robots to guide the waterjets and 3D printing technology to create intricate designs that were previously impossible to achieve manually. The future of water cutting in the stone industry looks bright, with the potential for more precise cuts, increased automation, and reduced costs. As technology continues to advance, the possibilities of what can be achieved with water cutting are endless.Conclusion:

Water cutting is a game-changer in the stone industry, offering a versatile and precise method for cutting through a variety of stone materials. It is an eco-friendly and cost-efficient method that produces little waste material compared to traditional cutting methods. The future of water cutting looks bright, with the potential for increased automation and more precise cuts, bringing a new level of creativity and innovation to the industry.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]