Stone Cutting And Polishing Equipment

Stone Cutting And Polishing Equipment

Stone cutting and polishing equipment are essential tools for anyone who works with stone materials such as granite, marble, and quartz. These tools allow for the precise cutting and shaping of stones, as well as polishing them to give them a smooth and shiny finish. In this article, we will take a closer look at stone cutting and polishing equipment, including their types, features, and benefits.Types of Stone Cutting and Polishing Equipment

There are several types of stone cutting and polishing equipment, each designed for specific purposes. Some of the most common types of equipment include:Diamond Saw Blades

Diamond saw blades are used for cutting stones with precision and accuracy. They feature small diamond particles that are embedded in the blade's edge, allowing it to cut through even the hardest stones. Diamond saw blades come in various sizes, shapes, and grits depending on the type of stone being cut.Stone Grinders

Stone grinders are used for shaping and smoothing stones. They feature a rotating wheel or disc that grinds away the rough edges of the stone to create a smooth, even surface. Stone grinders come in a range of sizes, from handheld to large floor models.Polishing Pads

Polishing pads are attached to a polishing machine and are used to give stones a shiny finish. They come in various grits, with higher grits producing a more polished finish. Polishing pads are made from different materials, including diamond, resin, and ceramic.Waterjet Cutting Machines

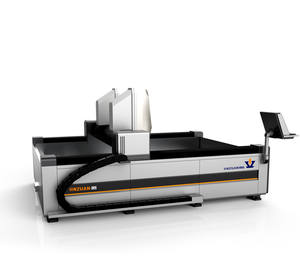

Waterjet cutting machines use high-pressure water to cut through stone materials. They are ideal for creating intricate designs and shapes in stone materials. Waterjet cutting machines are often used for creating custom stone countertops, floors, and other architectural features.Features of Stone Cutting and Polishing Equipment

Stone cutting and polishing equipment come with a range of features that make them efficient and effective. Some of the key features to look for include:Variable speed controls

Variable speed controls allow for greater precision and control when cutting or polishing stones. This feature enables you to adjust the speed of the equipment to match the hardness of the stone material.Dust collection systems

Dust collection systems are crucial for maintaining a clean and safe work environment. They collect the dust and debris created during the cutting and polishing process, reducing the amount of dust in the air.

Dust collection systems are crucial for maintaining a clean and safe work environment. They collect the dust and debris created during the cutting and polishing process, reducing the amount of dust in the air.

Automatic water supply

Automatic water supply systems keep the blades and discs cool during the cutting and polishing process, reducing the risk of overheating or damage to the equipment.Benefits of Stone Cutting and Polishing Equipment

Using stone cutting and polishing equipment offers a range of benefits for those who work with stone materials. Some of the key benefits include:Increased efficiency

Stone cutting and polishing equipment can help you work more efficiently, reducing the time and effort required to complete a stone-cutting or polishing project.

Greater precision and accuracy

With the right cutting and polishing equipment, you can achieve precise cuts and smooth finishes on even the hardest stone materials.Cost savings

Investing in stone cutting and polishing equipment can help you save money in the long run, as you'll be able to complete projects in-house rather than outsourcing them to third-party contractors.Conclusion

Stone cutting and polishing equipment are essential tools for anyone who works with stone materials. From diamond saw blades to waterjet cutting machines, there are a range of equipment options available to suit different needs and preferences. By investing in quality stone cutting and polishing equipment, you can achieve greater efficiency and precision, and enjoy a range of cost-saving benefits.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]