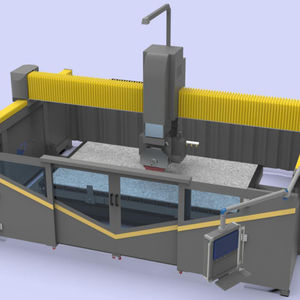

Sintered Stone Cutting Machine

Sintered Stone Cutting Machine: The Future of Stone Cutting Technology

Sintered stone has become increasingly popular in recent years due to its durability, color stability, and easy maintenance. However, cutting this material is not as simple as traditional natural stone. The unique properties of sintered stone require a specialized cutting machine. In this article, we will discuss the benefits of using a sintered stone cutting machine.

There are several benefits to using a sintered stone cutting machine, such as:

1. Precision cutting: The machine is equipped with specialized software that allows for precise cutting and shaping of the material. This ensures that the final product has clean edges and a uniform size.

2. Efficiency: Sintered stone cutting machines are designed to cut through the material quickly and with minimal waste. This saves time and reduces costs, making it an attractive option for manufacturers.

3. Versatility: Sintered stone cutting machines can be used to create a wide range of shapes and sizes. This means that manufacturers can create customized products for their clients, increasing their product offerings.

There are several benefits to using a sintered stone cutting machine, such as:

1. Precision cutting: The machine is equipped with specialized software that allows for precise cutting and shaping of the material. This ensures that the final product has clean edges and a uniform size.

2. Efficiency: Sintered stone cutting machines are designed to cut through the material quickly and with minimal waste. This saves time and reduces costs, making it an attractive option for manufacturers.

3. Versatility: Sintered stone cutting machines can be used to create a wide range of shapes and sizes. This means that manufacturers can create customized products for their clients, increasing their product offerings.

2. Waterjets: This type of machine uses a high-pressure water stream to cut through sintered stone. The water stream is mixed with abrasive material, which enables the machine to cut through the material quickly and efficiently.

2. Waterjets: This type of machine uses a high-pressure water stream to cut through sintered stone. The water stream is mixed with abrasive material, which enables the machine to cut through the material quickly and efficiently.

2. Cutting Capacity: Different machines have different cutting capacities. If you plan to cut through thicker material, you will need a machine with a higher cutting capacity.

2. Cutting Capacity: Different machines have different cutting capacities. If you plan to cut through thicker material, you will need a machine with a higher cutting capacity.

3. Software: The software that comes with the machine is essential in determining the precision and accuracy of the cuts. Choose a machine with software that is easy to use and provides accurate results.

3. Software: The software that comes with the machine is essential in determining the precision and accuracy of the cuts. Choose a machine with software that is easy to use and provides accurate results.

What is a Sintered Stone Cutting Machine?

A sintered stone cutting machine is a high-tech tool that uses diamond blades to cut and shape sintered stone. The blades are specially designed to handle the hardness and thickness of the material, which is why traditional stone cutting machines cannot be used.Benefits of using a Sintered Stone Cutting Machine

There are several benefits to using a sintered stone cutting machine, such as:

1. Precision cutting: The machine is equipped with specialized software that allows for precise cutting and shaping of the material. This ensures that the final product has clean edges and a uniform size.

2. Efficiency: Sintered stone cutting machines are designed to cut through the material quickly and with minimal waste. This saves time and reduces costs, making it an attractive option for manufacturers.

3. Versatility: Sintered stone cutting machines can be used to create a wide range of shapes and sizes. This means that manufacturers can create customized products for their clients, increasing their product offerings.

There are several benefits to using a sintered stone cutting machine, such as:

1. Precision cutting: The machine is equipped with specialized software that allows for precise cutting and shaping of the material. This ensures that the final product has clean edges and a uniform size.

2. Efficiency: Sintered stone cutting machines are designed to cut through the material quickly and with minimal waste. This saves time and reduces costs, making it an attractive option for manufacturers.

3. Versatility: Sintered stone cutting machines can be used to create a wide range of shapes and sizes. This means that manufacturers can create customized products for their clients, increasing their product offerings.

Types of Sintered Stone Cutting Machines

There are two main types of sintered stone cutting machines: bridge saws and waterjets. 1. Bridge Saws: This is one of the most common types of cutting machines used for sintered stone. The machine has a diamond blade that is mounted on a bridge that moves across the material. The blade cuts the material as it moves, and the machine can be programmed to cut the material into various shapes. 2. Waterjets: This type of machine uses a high-pressure water stream to cut through sintered stone. The water stream is mixed with abrasive material, which enables the machine to cut through the material quickly and efficiently.

2. Waterjets: This type of machine uses a high-pressure water stream to cut through sintered stone. The water stream is mixed with abrasive material, which enables the machine to cut through the material quickly and efficiently.

How to Choose a Sintered Stone Cutting Machine

Choosing the right sintered stone cutting machine can be challenging, given the various options available. Here are some factors to consider when making your decision: 1. Size: The size of the machine will depend on the size of the material you want to cut. If you plan to cut larger pieces of sintered stone, you will need a larger machine. 2. Cutting Capacity: Different machines have different cutting capacities. If you plan to cut through thicker material, you will need a machine with a higher cutting capacity.

2. Cutting Capacity: Different machines have different cutting capacities. If you plan to cut through thicker material, you will need a machine with a higher cutting capacity.

3. Software: The software that comes with the machine is essential in determining the precision and accuracy of the cuts. Choose a machine with software that is easy to use and provides accurate results.

3. Software: The software that comes with the machine is essential in determining the precision and accuracy of the cuts. Choose a machine with software that is easy to use and provides accurate results.

The Future of Sintered Stone Cutting Machines

As the demand for sintered stone continues to grow, the technology used to cut and shape it will also continue to evolve. The use of robotics and artificial intelligence is becoming increasingly common, allowing machines to make precise cuts without human intervention. This technology will not only improve efficiency but also reduce costs, making sintered stone more affordable for consumers.Conclusion

Sintered stone cutting machines are revolutionizing the stone cutting industry. Their precision, efficiency, and versatility make them an attractive option for manufacturers and consumers alike. As technology continues to evolve, we can expect to see even more advanced machines that will make cutting sintered stone even easier and more cost-effective.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]