Sandstone Cutting Machine

Sandstone Cutting Machine: A Game-Changing Solution for Stonework

Sandstone has been a favored construction material for centuries because of its durability, unique natural characteristics, and ease of cutting. Cutting sandstone with precision and speed can be a challenging task for stonemasons, builders, or DIY enthusiasts. Thankfully, technology has brought us sandstone cutting machines that revolutionize the way we work with stone.What Is a Sandstone Cutting Machine?

A sandstone cutting machine is a tool used to slice, carve, and shape sandstone to different sizes, shapes, and designs. It uses advanced technology to cut sandstone with great accuracy and speed, reducing manual labor and time spent on the job.Types of Sandstone Cutting Machines

There are different types of sandstone cutting machines available in the market. Most of them work on similar principles but differ in terms of their capabilities, size, and features. Some common types of sandstone cutting machines include:Wire Saw Machine

A wire saw machine is a popular sandstone cutting tool that uses a diamond wire loop to cut through the stone. The wire saw machine is highly versatile and can cut through various thicknesses and shapes of sandstone.Block Cutter Machine

A block cutter machine is designed to cut blocks of sandstone into smaller pieces. It operates on a hydraulic system and is capable of making straight or curved cuts.

A block cutter machine is designed to cut blocks of sandstone into smaller pieces. It operates on a hydraulic system and is capable of making straight or curved cuts.

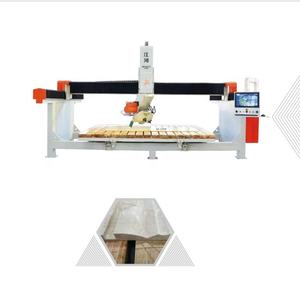

Bridge Saw Machine

A bridge saw machine is used to cut sandstone into different sizes and shapes. It is a versatile tool that can make precision cuts and is perfect for complex designs and large projects.Benefits of Sandstone Cutting Machine

Using a sandstone cutting machine offers several benefits, including:Accuracy and Precision

A sandstone cutting machine uses advanced technology to ensure accurate and precise cuts every time. This eliminates the need for manual cutting and reduces the risk of errors.Increased Efficiency

Speed is a significant advantage of a sandstone cutting machine. It can perform tasks faster than manual labor, leading to increased efficiency and higher productivity.Clean Cuts

Unlike traditional cutting methods, which can leave rough edges, a sandstone cutting machine produces much cleaner cuts, giving a superior finish to the project.Cost-Effective

While the initial investment for a sandstone cutting machine may seem high, it can pay off in the long run. Once purchased, a sandstone cutting machine can be used on multiple projects and can save significant amounts of money in labor costs.How to Choose a Sandstone Cutting Machine?

Choosing the right sandstone cutting machine can make a world of difference to your project. Here's what to consider when selecting one:Size

Sandstone cutting machines may come in various sizes and shapes, so it is essential to choose one that best fits the project requirements.Cutting Capacity

Different machines have different cutting capacities. Choose a machine that can handle the specific type, size, and shape of sandstone you will work with.Features

Opt for a machine with features that are essential for your project, such as water jets, laser guides, or automatic blade height adjustment.

Opt for a machine with features that are essential for your project, such as water jets, laser guides, or automatic blade height adjustment.

Budget

While investing in a sandstone cutting machine can be a game-changer, it's essential to choose one that fits your budget.Safety Tips for Using a Sandstone Cutting Machine

While sandstone cutting machines can increase work efficiency, they can also be dangerous if used improperly. Therefore, here are some safety tips to keep in mind when using a sandstone cutting machine:Wear Protective Gear

Always wear personal protective equipment, such as goggles, gloves, and earplugs.

Read the Manual

Read the manual before using a sandstone cutting machine. It provides critical safety and operational instructions.Stay alert and Focused

Stay alert and focused when using a sandstone cutting machine. Avoid wearing loose clothing or jewelry that can get caught in the machine.

Stay alert and focused when using a sandstone cutting machine. Avoid wearing loose clothing or jewelry that can get caught in the machine.

Follow operational Procedures

Follow proper operational procedures to prevent accidents.Conclusion

A sandstone cutting machine can be an excellent investment for stonemasons, architects, and builders looking to increase productivity, efficiency, and safety. Choose the right type of machine that suits your specific needs, and always remember to follow safety guidelines to prevent accidents. With the right machine and safety measures in place, you can achieve precision, accuracy, and speed in your sandstone cutting projects.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]