Laser Stone Cutter

Laser Stone Cutter: The Next Must-Have Tool for Stone Fabrication

If you're in the business of stone fabrication, then you know how important precision and accuracy are to the quality of your work. Introducing the Laser Stone Cutter, the latest tool that can help take your stone cutting to the next level. Using a computer-controlled laser beam, it provides unparalleled precision and speed in the cutting of various types of stone.

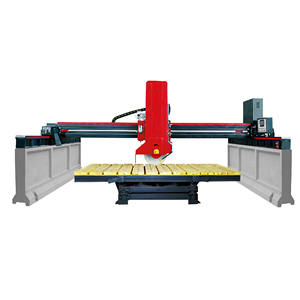

What is a Laser Stone Cutter?

A Laser Stone Cutter is a specialized machine that uses a laser beam to accurately and efficiently cut a wide variety of stones, including marble, granite, and quartz. With the ability to cut through a variety of materials, it can be used in a range of applications, from residential kitchen countertops to large commercial building projects.

A Laser Stone Cutter is a specialized machine that uses a laser beam to accurately and efficiently cut a wide variety of stones, including marble, granite, and quartz. With the ability to cut through a variety of materials, it can be used in a range of applications, from residential kitchen countertops to large commercial building projects.

How Does It Work?

The Laser Stone Cutter works by using a focused laser beam to vaporize the stone's surface layer. This produces a clean and precise cut that can be used for a range of stone fabrication purposes. By using a series of mirrors and lenses, the laser beam can be directed to the exact location where the cut needs to be made. The machine is computer-controlled and can be programmed to cut complex shapes and designs with ease.Benefits of Using a Laser Stone Cutter

There are numerous benefits to using a Laser Stone Cutter, including:

There are numerous benefits to using a Laser Stone Cutter, including:

Precision:

The Laser Stone Cutter can cut stone with unparalleled precision, resulting in customized and intricate designs not possible with traditional cutting tools. This precision serves to improve the overall quality of your work and can help you stand out from the competition.Efficiency:

This tool can cut stone with incredible speed, without sacrificing accuracy. It can process large slabs in just a fraction of the time compared to traditional saws and routers, resulting in increased productivity and faster job turnaround times.Safety:

With a Laser Stone Cutter, workers are kept safe as there is no physical contact between the machine and the operator during the cutting process. This reduces the chances of injury from operating heavy machines, which is common in traditional cutting methods.Types of Laser Stone Cutters

There are several types of Laser Stone Cutters available on the market, each with its own set of features and benefits. Two of the most widely used types include:Nd:YAG Laser Cutters:

Nd:YAG Laser Cutters are popular for cutting through harder stones and materials, such as granite or quartz. These cutters use a crystal known as neodymium-doped yttrium aluminum garnet to create the laser beam.CO2 Laser Cutters:

CO2 Laser Cutters are more versatile and can be used to cut a wide range of materials, including softer stones and materials, such as ceramic or porcelain. These cutters use a carbon dioxide mixture to create the laser beam.Tips on Choosing a Laser Stone Cutter

When selecting a Laser Stone Cutter, there are several factors to consider, including:

Material to be cut:

Consider the type of stone and other materials you will be cutting, as this can determine which type of laser cutter you should choose.Size of cutting bed:

Laser cutters come in a variety of sizes, so consider the size of the cutting bed required for your workload.Power:

Choose a laser cutter with sufficient power to cut through the types of materials you work with.Conclusion

The Laser Stone Cutter is a must-have tool for stone fabrication professionals, providing superior precision, efficiency, and safety in the cutting of various types of stone. By incorporating this innovative tool into your workflow, you can take your stone cutting capabilities to the next level and stay ahead of the competition.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]