Cutting Rocks With Water

Cutting Rocks with Water: An Innovative Technology

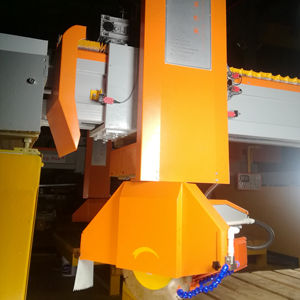

Cutting rocks has always been a challenging task, with traditional methods such as drilling, sawing and blasting being time-consuming, costly and potentially dangerous. However, with the advent of water jet cutting technology, cutting rocks has never been quicker, more efficient or safer than before. Water jet cutting technology is a process that involves the use of high-pressure water streams to cut through rocks of varying hardness. Below are some of the ways water jet cutting technology is transforming the rock cutting industry.How Water Jet Cutting Technology Works

Water jet cutting technology involves the use of a water jet cutter, which pressurizes water to about 60,000 PSI, and in some cases, combines it with abrasive particles, such as garnet. The pressurized water is then directed towards the rock surface using a nozzle, which can be moved along the rock surface to create the desired cuts.The Benefits of Water Jet Cutting Technology

Water jet cutting technology has numerous benefits, including:Accuracy

Water jet cutting technology produces precise cuts that are virtually free of mistakes. This is because it allows for better control over the cutting process, resulting in a cleaner and more accurate cut.Faster Cutting Time

Compared to traditional methods, water jet cutting saves time significantly by cutting through rocks at a faster rate. Quick cutting speeds result in quicker turnaround times for projects, allowing for more efficient processes in the rock cutting industry.Cost-Effective

Water jet cutting technology requires very little set-up time and uses minimal energy, making it a cost-effective cutting method. It also lowers operating costs because it doesn't require the use of any cutting oils or coolants.

Water jet cutting technology requires very little set-up time and uses minimal energy, making it a cost-effective cutting method. It also lowers operating costs because it doesn't require the use of any cutting oils or coolants.

Safety

Compared to other cutting methods, water jet cutting is much safer as it doesn't produce any dust, fumes or harmful particulates, which can be dangerous to the operators and the environment. It also eliminates the risk of overheating, which can lead to fires.

Compared to other cutting methods, water jet cutting is much safer as it doesn't produce any dust, fumes or harmful particulates, which can be dangerous to the operators and the environment. It also eliminates the risk of overheating, which can lead to fires.

Applications of Water Jet Cutting Technology in Rock Cutting

Water jet cutting technology has widespread applications in various rock cutting industries, including:

Construction Industry

Water jet cutting is used extensively in the construction industry for cutting and shaping rocks, bricks and other materials. It is often used in road construction, dam building and other infrastructure projects that require precise cuts.

Stone Industry

Water jet cutting technology is used in the stone industry for cutting, carving and shaping various types of stones, including granite, marble, limestone and sandstone. It allows for clean and precise cuts, making it easy to create intricate designs and patterns.Exploration Industry

The exploration industry uses water jet cutting technology for drilling and cutting through solid rock, especially in mining operations. It is a faster and more efficient method than traditional drilling methods, allowing for quicker access to valuable mineral deposits.Conclusion

Water jet cutting technology is a game-changer in the rock cutting industry, revolutionizing the way rocks are cut and shaped. It is an efficient, cost-effective and precise cutting method that produces clean and accurate cuts. It has multiple applications, making it a versatile technology for the construction, stone and exploration industries.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]