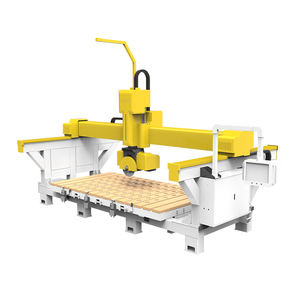

Table Marble Cutting Machine

Table Marble Cutting Machine: The Future of Stone Processing

If you're in the stone processing industry, you're likely familiar with the traditional way of cutting marble using handheld saws. However, with advancements in technology, a table marble cutting machine has proven to be the future of stone processing. Here's an in-depth look at what a table marble cutting machine is, the benefits that it offers, and how it can help you take your stone processing game to the next level.What is a Table Marble Cutting Machine?

A table marble cutting machine is a specialized cutting tool that is designed to create precise cuts on marble slabs. The machine consists of a flat table with a diamond-coated saw blade that is mounted on an arbor above the table. The blade is attached to a motor that moves it back and forth across the surface of the marble slab, allowing for precise cuts to be made.Benefits of Using a Table Marble Cutting Machine

There are several benefits to using a table marble cutting machine compared to traditional handheld saws. These benefits include:

There are several benefits to using a table marble cutting machine compared to traditional handheld saws. These benefits include:

Accuracy

One of the main advantages of a table marble cutting machine is its accuracy. The machine allows for precise cuts to be made, ensuring that the marble slabs are of consistent size and shape. This is particularly important when working on large-scale projects where consistency and accuracy are key.Efficiency

A table marble cutting machine is also incredibly efficient. The machine is designed to cut through marble slabs quickly and easily, reducing the amount of time and effort required to complete a project. This means that you can take on more projects and increase your overall productivity.Safety

Working with handheld saws can be dangerous, particularly when working with large marble slabs. A table marble cutting machine eliminates the need for handheld saws, reducing the risk of accidents and injuries.Versatility

Table marble cutting machines are incredibly versatile and can be used to cut a wide range of materials, including granite, quartz, and porcelain. This makes the machine a valuable asset for any stone processing business.

Table marble cutting machines are incredibly versatile and can be used to cut a wide range of materials, including granite, quartz, and porcelain. This makes the machine a valuable asset for any stone processing business.

How to Choose the Right Table Marble Cutting Machine

When choosing a table marble cutting machine, there are several factors to consider. These include the size of the machine, the quality and size of the blade, the material being cut, and the overall build quality of the machine.

When choosing a table marble cutting machine, there are several factors to consider. These include the size of the machine, the quality and size of the blade, the material being cut, and the overall build quality of the machine.

Size of the Machine

The size of the table marble cutting machine you require will depend on the size of the marble slabs you need to cut. Consider the size of the largest slab you will be working with and choose a machine with a table large enough to accommodate it.Quality and Size of the Blade

The quality and size of the blade are also important factors to consider. Choose a machine with a high-quality diamond-coated blade that is large enough to cut through the thickest slab you will be working with.Material Being Cut

Consider the type of material you will be cutting and choose a machine that is capable of cutting through it. Some machines are designed specifically for cutting marble, while others are more versatile and can cut a range of materials.Build Quality

Finally, consider the overall build quality of the machine. Look for a machine that is well-built, with a sturdy frame and high-quality components. This will ensure that the machine is durable and can withstand the demands of regular use.Conclusion

Overall, a table marble cutting machine is a valuable asset for any stone processing business. It offers a range of benefits, including accuracy, efficiency, safety, and versatility. When choosing a machine, consider factors such as the size of the machine, the quality and size of the blade, the material being cut, and the overall build quality. With the right machine, you can take your stone processing game to the next level and increase your overall productivity and profitability.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]