Marble Cnc Cutting

A Comprehensive Guide on How It Works and Its Benefits

Marble is a popular material in construction, architecture, and art projects because of its durability, elegance, and aesthetic value. One way to cut marble accurately and efficiently is through marble CNC cutting. This process involves using a computer numerical control (CNC) machine to cut and shape marble based on digital designs. In this article, we will discuss the benefits and features of marble CNC cutting, and how it works.What is Marble CNC Cutting?

Marble CNC cutting is a process of cutting marble using a computer-controlled cutting machine. The process is straightforward and efficient, where digital designs are fed into the machine using computer-aided design (CAD) software. The machine uses high-speed rotating cutters, which are programmed to make precise cuts into the marble based on the design. The process produces clean edges, intricate shapes, and accurate measurements in comparison to traditional manual marble cutting methods.

How Does Marble CNC Cutting Work?

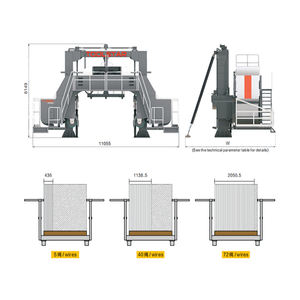

Marble CNC cutting involves a series of steps, including: 1. Designing the digital design -The first step is to create a digital design using CAD software. The digital design entails putting together the various design details, such as shapes, edges, dimensions, and cutouts. CAD software is widely used because it allows precise measurements and shapes that would be difficult to achieve manually. 2. Getting the right machine - The second step is to choose the right CNC machine for the cutting job. There are different types of CNC machines in the market, with different sizes, shapes, and types of cutting tools. The right machine will depend on the design details and the thickness and size of the marble. 3. Fixing the marble - Once the digital design is made and the machine is ready, the marble is fixed onto the bed of the machine. The marble is fixed in place, either through clamps or vacuum suction systems that hold the marble firmly in place. 4. Setting the parameters - The next step is to set the parameters, such as the spindle speed, feed rate, cutting depth, and coolant use. The parameters are set according to the digital design, the type of marble, and the type of cutting tools. 5. Running the machine - Once the parameters are set, the machine is turned on to start the cutting process. The machine will follow the digital design and cut the marble as programmed. The machine will make different cuts, such as drilling, sawing, or grinding, depending on the design features.

Benefits of Marble CNC Cutting

There are several benefits to using marble CNC cutting, including: 1. Precision and accuracy - Marble CNC cutting produces accurate and precise cuts that are difficult to achieve using manual methods. CNC machines operate based on programmed digital designs, ensuring consistent and uniform results with every cut. 2. Time-efficient - CNC machines are time-efficient and produce accurate designs much faster compared to manual methods. The process is also automated, which eliminates the need for multiple operators during the cutting process. 3. Reduced waste - Marble CNC cutting produces less waste than traditional cutting methods. The digital design allows the operator to optimize the marble slab for minimal waste, and the cutting is precise, which minimizes material loss. 4. Versatility - Marble CNC cutting allows for a wide range of designs and shapes, including curves, patterns, and three-dimensional designs. The cutting tools can also be changed to produce different types of cuts, making it incredibly versatile for any design project.Applications of Marble CNC Cutting

Marble CNC cutting is widely used in various industries, including but not limited to: 1. Architecture - Marble CNC cutting is used to create intricate and precise marble designs for various architectural projects, including flooring, tiles, and wall cladding. 2. Art and design - Marble CNC cutting is popular in the design industry, where it is used to create sculptures, statues, and other artistic objects. 3. Commercial and residential construction - Marble CNC cutting is used to create precise designs for kitchen countertops, wall panels, and bathroom vanity tops. 4. Restoration - Marble CNC cutting is used in restoration projects to replicate and replace missing or damaged parts of historical buildings and sculptures.Conclusion

Marble CNC cutting is an advanced and innovative technology that produces precise and accurate designs while reducing material waste and time consumption. The process is versatile and can be used in any industry where marble cutting and shaping are needed. The digital designs allow for customization and flexibility, making it a popular choice for architects, designers, contractors, and artists. If you're looking for precise and efficient marble cutting, then consider Marble CNC cutting for your next project. User :Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]