Waterjet Granite Cutting Machine

Waterjet Granite Cutting Machine: The Perfect Solution for Granite Fabrication

Looking for the perfect machine to help you with your granite cutting needs? The waterjet granite cutting machine is the answer. This advanced and powerful machine is a reliable and effective solution that is used widely in the granite fabrication industry. In this article, we'll explain everything you need to know about the waterjet granite cutting machine.What is a Waterjet Granite Cutting Machine?

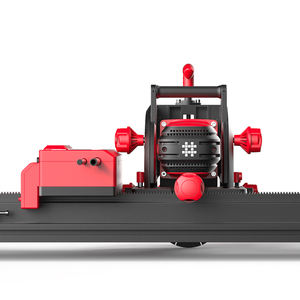

A waterjet granite cutting machine is a high-tech cutting tool that uses a jet of water mixed with an abrasive substance to cut through granite. The machine is designed to produce clean, precise cuts on granite slabs of varying thickness, making it a popular choice for granite fabricators.

A waterjet granite cutting machine is a high-tech cutting tool that uses a jet of water mixed with an abrasive substance to cut through granite. The machine is designed to produce clean, precise cuts on granite slabs of varying thickness, making it a popular choice for granite fabricators.

How does it work?

The machine uses a high-pressure pump to force water through a small nozzle, where it is mixed with abrasive particles such as garnet. The resulting abrasive water jet is then directed at the granite material, cutting through it quickly and accurately.

The machine uses a high-pressure pump to force water through a small nozzle, where it is mixed with abrasive particles such as garnet. The resulting abrasive water jet is then directed at the granite material, cutting through it quickly and accurately.

Advantages of Waterjet Granite Cutting Machines

- Precise cuts: The waterjet granite cutting machine produces very precise cuts on granite slabs, leaving a clean and smooth finish. - Versatile: The machine can cut through granite slabs of different thicknesses and shapes, allowing fabricators to create custom designs. - Minimal material loss: Due to the precision of the machine, there is minimal material loss during the cutting process, which reduces waste and saves money. - Environmentally friendly: The machine produces no hazardous waste, making it a safer and more environmentally friendly option compared to other cutting methods.Applications of Waterjet Granite Cutting Machines

Waterjet granite cutting machines are used in various applications such as: - Kitchen countertops - Bathroom countertops - Fireplace surrounds - Flooring and wall cladding - Stairs and stepsMaintenance of Waterjet Granite Cutting Machines

Proper maintenance of waterjet granite cutting machines is crucial to ensure they operate effectively and safely. Routine maintenance tasks include checking and replacing worn-out nozzles and replacing abrasive particles regularly. Regular cleaning and inspection of the machine's components, such as pumps and hoses, are also necessary.Conclusion

In conclusion, waterjet granite cutting machines are the perfect solution for granite fabricators looking for a precise, versatile, and environmentally friendly cutting tool. With its many advantages, it has revolutionized the way granite materials are cut and fabricated. Ensure you choose a quality machine and perform proper maintenance to enjoy its benefits fully.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]