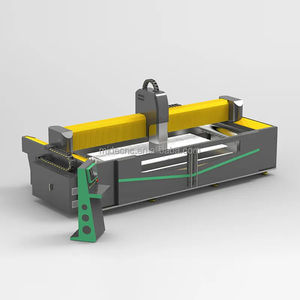

Multi Wire Saw Granite Cutting Machine

Understanding the Multi Wire Saw Granite Cutting Machine

The process of cutting granite blocks for various purposes can be a daunting task. But, with the advancement of technology, the use of multi-wire saw granite cutting machines has made the process less tedious and more efficient. In this article, we will explore the machine's features, working principles, and benefits.

What is a Multi Wire Saw Granite Cutting Machine?

A multi-wire saw granite cutting machine is a state-of-the-art machine used for cutting granite blocks into slabs of various thicknesses. The machine uses diamond wires to make precise and clean cuts, making it possible to produce slabs with a thickness range of 2-10mm. This type of machine is predominantly used in the granite industry for cutting slabs of standard and customized sizes.

How Does it Work?

The multi-wire saw granite cutting machine consists of multiple diamond wire saws of various thicknesses that cut through granite blocks with great precision. The machine is automated and features a high-speed computer that manages the entire cutting process. The wire saws are threaded through a series of pulleys and powered by electric motors, which enable them to move in a back and forth motion through the granite block. The diamond wires cut through the granite material leaving smooth, clean-cut slabs.

The multi-wire saw granite cutting machine consists of multiple diamond wire saws of various thicknesses that cut through granite blocks with great precision. The machine is automated and features a high-speed computer that manages the entire cutting process. The wire saws are threaded through a series of pulleys and powered by electric motors, which enable them to move in a back and forth motion through the granite block. The diamond wires cut through the granite material leaving smooth, clean-cut slabs.

Features of the Multi-Wire saw Granite Cutting Machine

The multi-wire saw granite cutting machine is equipped with various features that make it an efficient machine to use. Some of the essential features include:

The multi-wire saw granite cutting machine is equipped with various features that make it an efficient machine to use. Some of the essential features include:

- Multiple wire saws for producing several slabs at once.

- Diamond wires that cut through granite cleanly and precisely.

- A high-speed computerized system that manages the entire process.

- An automatic wire tensioning system to ensure that the wires remain tight during the cutting process.

- An automatic lubrication system to reduce friction during the cutting process.

Benefits of the Multi-Wire Saw Granite Cutting Machine

There are several benefits that come with using a multi-wire saw granite cutting machine. These benefits include:- Efficiency: The machine produces multiple slabs of granite at once, reducing the time taken to cut the blocks.

- Precision: The diamond wires cut through granite with great precision, producing clean and smooth-cut slabs.

- Customization: The machine can produce customized slab sizes, depending on the client's requirements.

- Reduced waste: The machine produces less waste as compared to other cutting methods, resulting in lower production costs.

- Eco-friendly: The machine produces less waste which means that there is less environmental pollution.

Applications of the Multi-wire Saw Granite Cutting Machine

The multi-wire saw granite cutting machines have several applications, including:- Construction: The machine produces granite slabs that are used in various construction projects.

- Design: The machine produces custom granite slabs used in interior design projects.

- Art: The machine is used by artists to produce granite pieces for sculptures and other artwork.

- Memorials: The machine is used to produce custom granite slabs for memorials and gravestones.

Conclusion

The multi-wire saw granite cutting machine is a revolutionary piece of equipment that has changed the granite cutting process. The machine's precision, efficiency, and customization capabilities make it an essential tool in the granite industry. If you are in the granite business, it is advisable to invest in a multi-wire saw granite cutting machine to reap the associated benefits.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]