Granite Side Cutting

Granite Side Cutting: A Critical Process in Stone Fabrication

Granite side cutting is an essential step in the stone fabrication process. This process involves cutting the sides of the granite slab to create straight edges that can be used for countertops, walls, and other stone products. In this article, we will explore the significance of side cutting and the different techniques used in the process.

The Importance of Granite Side Cutting

Granite side cutting is essential in the stone fabrication industry because it creates the straight edges necessary for the creation of stone products. It is a critical step in the process of granite fabrication, and without it, stone products such as countertops and walls would not have the precise shapes and sizes required for their intended purposes.The Side Cutting Process

Side cutting is performed using a diamond blade saw. The saw is first wetted with water to prevent the blade from overheating and to reduce dust. The granite slab is then placed on a flat surface and secured in place using clamps. The saw is then set to the desired depth, and the blade's motor is turned on, and the saw is slowly guided through the granite slab, resulting in straight and smooth edges.

Different Techniques Used in Side Cutting

There are different techniques used in granite side cutting. These techniques include:

There are different techniques used in granite side cutting. These techniques include:

- Manual Cutting - Manual cutting involves cutting the granite slabs manually using hand-held saws. This technique is used for smaller jobs and non-commercial purposes.

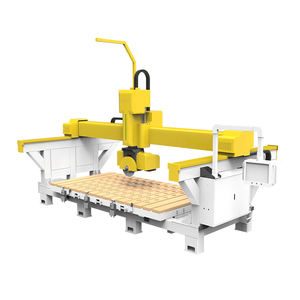

- Machine Cutting - Machine cutting is the most common technique used in the granite fabrication industry. It involves using machine-powered saws for large-scale jobs, and the process is easy and efficient.

The Benefits of Granite Side Cutting

Granite side cutting offers several benefits to the stone fabrication industry. Here are a few of the most significant benefits:- Precision - Side cutting using a diamond blade saw ensures precision in cutting granite slabs, making it a crucial process in achieving the exact shape and size required in stone fabrication.

- Efficiency - Granite side cutting is a quick and efficient process. It allows the stone fabricator to produce numerous pieces of granite slabs in a short amount of time, reducing waiting periods for customers.

- Clean Cutting - The use of diamond blades in granite cutting reduces dust and creates a clean and smooth edge, enhancing the aesthetic appeal of the final product.

Conclusion

In conclusion, granite side cutting is a critical and necessary process in granite stone fabrication. It enables fabricators to create pieces of stone accurately and efficiently to meet customer demands. The use of diamond blade saws in the manufacturing process ensures precision, efficiency, and clean cutting, resulting in top-quality finished products.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]