Granite Machine Cutter

Granite Machine Cutter: The Ultimate Cutting Solution

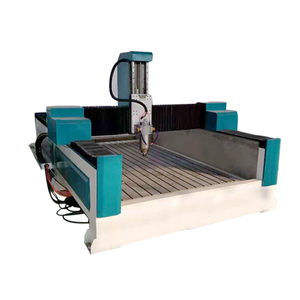

The Granite Machine Cutter is a highly advanced cutting tool used for precision cutting and engraving of granite surfaces. It uses diamond blades to cut through granite with exceptional accuracy and speed, making it an essential tool for professionals in the stone cutting and engraving industry. In this guide, we'll take a closer look at this cutting-edge machine and explore its key features, applications, and benefits.What is a Granite Machine Cutter?

A Granite Machine Cutter is a cutting-edge tool designed to cut and engrave complex shapes into granite surfaces. It is equipped with high-quality diamond blades that cut through the granite surface with exceptional accuracy and speed. This machine is often used in commercial and residential settings for a range of applications, including engraving headstones, creating custom-designed stone countertops, and producing intricate designs on stone walls or statues.

Features of the Granite Machine Cutter

The Granite Machine Cutter comes equipped with a range of features that make it one of the most advanced cutting tools on the market. Some of its key features include:

- High-quality diamond blades for precise cutting

- Precision positioning system for accurate cutting and engraving

- Variable speed control for optimal cutting speed

- Compatible with a range of design software

- Easy to use interface and controls

Applications of the Granite Machine Cutter

The Granite Machine Cutter is an essential tool for a wide range of applications in both commercial and residential settings. Some of the most common applications for this machine include:- Engraving personalized inscriptions onto headstones and monuments

- Creating custom-designed stone countertops for kitchens and bathrooms

- Carving intricate designs and patterns onto stone walls or statues

- Cutting granite tiles for flooring and backsplashes

Benefits of the Granite Machine Cutter

The Granite Machine Cutter offers a range of benefits that make it an excellent investment for professionals in the stone cutting industry. Some of the key benefits of this machine include:

The Granite Machine Cutter offers a range of benefits that make it an excellent investment for professionals in the stone cutting industry. Some of the key benefits of this machine include:

- Exceptional precision and accuracy

- The ability to cut and engrave highly intricate designs and shapes

- Faster cutting and engraving times than traditional methods

- Reduced risk of damage to the granite surface

- Increased productivity and efficiency

How the Granite Machine Cutter Works

The Granite Machine Cutter works by using high-quality diamond blades to cut precisely into the granite surface. The machine is programmed with the specific design or pattern to be cut or engraved, and the granite surface is placed on the machine. The precision positioning system accurately places the blades onto the surface of the granite, where they can cut or engrave the desired pattern.

The Granite Machine Cutter works by using high-quality diamond blades to cut precisely into the granite surface. The machine is programmed with the specific design or pattern to be cut or engraved, and the granite surface is placed on the machine. The precision positioning system accurately places the blades onto the surface of the granite, where they can cut or engrave the desired pattern.

Maintenance of the Granite Machine Cutter

Proper maintenance of a Granite Machine Cutter is essential for its ongoing performance and longevity. It is recommended that the machine is cleaned regularly, and the blades are sharpened or replaced as needed to ensure optimal cutting performance.Conclusion

The Granite Machine Cutter is a highly advanced and efficient tool for cutting and engraving granite surfaces. It offers a range of features and benefits that make it an excellent investment for professionals in the stone cutting industry. Whether you're engraving headstones or creating custom-designed stone countertops, the Granite Machine Cutter can help you achieve exceptional results with speed and precision.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]