Granite Laser Cutting Machine

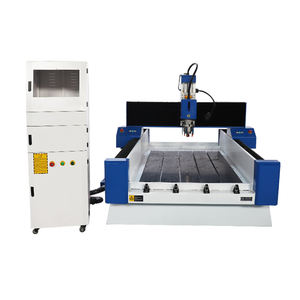

Granite Laser Cutting Machine: The Innovative Solution for Precision Cutting

Granite is a popular material used in various construction and decoration projects due to its durability, hardness, and resistance to extreme temperatures. However, cutting and shaping this dense material can be challenging, especially if you're dealing with complex designs. Fortunately, the advent of granite laser cutting machines has revolutionized the stone fabrication industry, delivering precise, fast, and cost-effective cutting solutions. In this article, we'll explore the features, benefits, and applications of granite laser cutting machines.How Granite Laser Cutting Machines Work

Granite laser cutting machines use a highly focused laser beam to cut through granite slabs, blocks, tiles, or sheets with exceptional accuracy and speed. The laser beam is directed onto the surface of the granite material using mirrors, lenses, and other optical components. The high energy of the laser vaporizes the granite, leaving a smooth and clean cut edge. The laser cutting process is computer-controlled, which allows for precise and repeatable cuts, even on highly detailed or intricate designs.The Advantages of Granite Laser Cutting Machines

Granite laser cutting machines offer several advantages over traditional cutting methods, such as waterjet cutting, diamond saw cutting, or abrasive cutting. Some of these benefits include:- High precision: Laser cutting machines can achieve a resolution of up to 0.1mm, which makes them ideal for intricate or delicate designs.

- Speed: Laser cutting machines can cut through granite at a faster rate than other cutting tools, which translates to shorter lead times and increased productivity.

- Clean cuts: Laser cutting produces a smooth and chip-free cut edge, which requires minimal or no finishing work.

- Flexibility: Laser cutting can be used to cut any shape or contour, making it ideal for custom or complex projects.

- Cost-effective: Laser cutting machines require less maintenance and have lower operating costs than other cutting tools, which makes them a cost-effective choice in the long run.

Applications of Granite Laser Cutting Machines

Granite laser cutting machines can be used in various applications, including:- Kitchen countertops: Laser cutting can produce intricate and precise cuts for sink and stove openings, edges, and shapes.

- Bathroom vanities: Laser cutting can create unique and personalized designs for sink cutouts, edges, and backsplashes.

- Flooring and walls: Laser cutting can create custom designs and patterns for granite tiles and slabs, which can be used for flooring and wall cladding.

- Monuments and memorials: Laser cutting can produce intricate engravings, lettering, and designs on granite stones for monuments, plaques, and memorials.

- Decorative items: Laser cutting can be used to create sculptures, vases, bowls, and other decorative items from granite blocks or sheets.

Choosing the Right Granite Laser Cutting Machine

When selecting a granite laser cutting machine, there are several factors to consider, including:- Laser power: The laser power determines the cutting speed and thickness of the granite material.

- Cutting bed size: The cutting bed size should be large enough to accommodate the size and quantity of granite material you plan to cut.

- Software compatibility: The cutting machine should be compatible with the CAD/CAM software you're using to design the cutting patterns.

- Manufacturer support: Choose a reputable manufacturer with a proven track record in the stone fabrication industry and excellent customer service and support.

Maintaining Granite Laser Cutting Machines

Maintaining your granite laser cutting machine is essential for ensuring its longevity and efficiency. Some tips for maintaining your cutting machine include:- Regular cleaning and lubrication of the moving parts, such as the gantry, rails, and bearings.

- Replace the fume extraction filters and clean the optics regularly.

- Calibrate the laser beam and cutting bed regularly to ensure optimal performance.

- Perform routine maintenance checks and inspections to detect and address any issues early.

Conclusion

Granite laser cutting machines offer a precise, fast, and cost-effective solution for cutting and shaping granite material for various applications, including kitchen countertops, bathroom vanities, flooring, monuments, and decorative items. When selecting a cutting machine, consider factors such as laser power, cutting bed size, software compatibility, and manufacturer support. Remember to maintain your cutting machine regularly to ensure its longevity and efficiency.

Granite laser cutting machines offer a precise, fast, and cost-effective solution for cutting and shaping granite material for various applications, including kitchen countertops, bathroom vanities, flooring, monuments, and decorative items. When selecting a cutting machine, consider factors such as laser power, cutting bed size, software compatibility, and manufacturer support. Remember to maintain your cutting machine regularly to ensure its longevity and efficiency. Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]