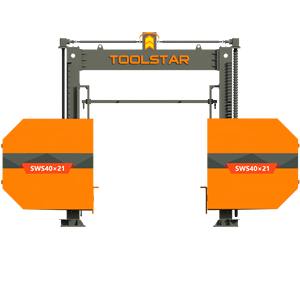

Granite Cutting Table Saw

Granite Cutting Table Saw: Advancements in Technology and Applications

Granite is a dense, hard stone that is widely used in various construction projects in countertops, flooring, and walls. It is known for its durability, heat resistance, and aesthetic appeal. However, the challenging task lies in cutting and shaping granite slabs to fit specific dimensions and designs. This is where a granite cutting table saw comes in handy. In this article, we will discuss the advancements in technology and applications of granite cutting table saws.How Does a Granite Cutting Table Saw Work?

A granite cutting table saw is a circular saw blade that is mounted on a table. The saw blade typically has diamond-coated edges to cut through the hard surface of the granite. The saw blade can be adjusted for height and angle to cut various shapes and sizes. A water pump system is used to cool the blade and minimize the amount of dust created during the cutting process.Advancements in Technology

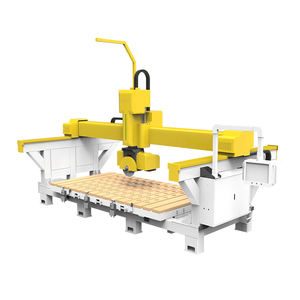

The development of laser-guided cutting technology provides more precision and accuracy when cutting granite slabs. The laser guide ensures that the saw blade is aligned with the intended cut line. This reduces the chance of errors and mistakes, allowing for more efficient and effective cutting. Another technological advancement in granite cutting saws is the use of computer numerical control (CNC) technology. This enables the saw blade to be programmed using software to cut complex shapes and designs automatically. This technology has revolutionized the precision and efficiency of granite cutting, allowing for the creation of more intricate and detailed designs.

Applications of Granite Cutting Table Saw

Granite cutting table saws are used in a wide range of industries, including construction, manufacturing, and stone fabrication. They are commonly used for cutting granite countertops, backsplashes, and tiles for kitchens and bathrooms. In addition, they are used for creating monuments, sculptures, and other ornamental designs.Factors to Consider When Selecting a Granite Cutting Table Saw

When selecting a granite cutting table saw, there are several factors to consider. The first is the size of the saw blade, which will determine the maximum size of the granite slab that can be cut. The second is the power of the motor, which will determine the thickness of granite that can be cut. The third is the water pump system, which should be efficient and minimize the amount of dust created during the cutting process.

When selecting a granite cutting table saw, there are several factors to consider. The first is the size of the saw blade, which will determine the maximum size of the granite slab that can be cut. The second is the power of the motor, which will determine the thickness of granite that can be cut. The third is the water pump system, which should be efficient and minimize the amount of dust created during the cutting process.

Maintenance of Granite Cutting Table Saw

To ensure the longevity and efficiency of a granite cutting table saw, regular maintenance is essential. This includes keeping the water pump system clean, replacing worn-out saw blades, and oiling moving parts. It is also important to observe safety guidelines, such as wearing protective gear and securing the granite slabs during cutting.Conclusion

In summary, granite cutting table saws are essential tools in stone fabrication and construction. The advancements in technology have made the cutting process more precise, efficient, and versatile. When selecting a granite cutting table saw, it is crucial to consider factors such as blade size, power, and water pump system. With proper maintenance and observance of safety guidelines, a granite cutting table saw can provide years of efficient service, producing high-quality granite products for various applications.

In summary, granite cutting table saws are essential tools in stone fabrication and construction. The advancements in technology have made the cutting process more precise, efficient, and versatile. When selecting a granite cutting table saw, it is crucial to consider factors such as blade size, power, and water pump system. With proper maintenance and observance of safety guidelines, a granite cutting table saw can provide years of efficient service, producing high-quality granite products for various applications. Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]