Granite Cutting Machine

Efficient Granite Cutting with a Granite Cutting Machine

Granite is a hard and durable stone that has been used in construction and decoration for centuries. However, cutting it to the desired shape and size requires specialized equipment. That is why many professionals choose to use a granite cutting machine. A granite cutting machine is a powerful tool that is specifically designed to cut through granite with ease. In this article, we will explore the features and benefits of using a granite cutting machine.

What is a Granite Cutting Machine?

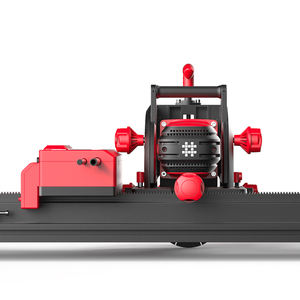

A granite cutting machine is a powerful and efficient tool that is designed specifically to cut through granite. It is made up of an electric motor that drives a diamond blade, which is used to cut through the hard surface of the granite. The machine can be operated manually or automatically, and it comes in different sizes and configurations depending on the intended use.

A granite cutting machine is a powerful and efficient tool that is designed specifically to cut through granite. It is made up of an electric motor that drives a diamond blade, which is used to cut through the hard surface of the granite. The machine can be operated manually or automatically, and it comes in different sizes and configurations depending on the intended use.

The Benefits of Using a Granite Cutting Machine

Using a granite cutting machine has several benefits, including:- Efficiency: A granite cutting machine can cut through granite quickly and with minimal effort. This means that you can achieve more work in a shorter period.

- Precision: With the diamond blade, you can achieve precise cuts with little to no chipping, resulting in a clean, finished edge.

- Flexibility: Granite cutting machines can be used on a variety of granite sizes and shapes.

- Safety: When operated correctly and with the appropriate safety equipment, a granite cutting machine is a safe tool to use.

- Durability: A high-quality granite cutting machine is built to last, even with regular use.

Types of Granite Cutting Machines

There are different types of granite cutting machines available in the market. The most common types include:- Bridge saws: These are large machines that are designed to make precise cuts on large slabs of granite. They are commonly used in the construction industry.

- Wire saws: These are versatile machines that can be used to cut granite into different shapes and sizes. They work by using a wire that is coated in diamond abrasive, which is used to cut through the granite.

- Handheld saws: These are portable machines that are used for smaller cutting tasks. They are easy to use and transport, making them ideal for on-site work and smaller projects.

Factors to Consider When Choosing a Granite Cutting Machine

When choosing a granite cutting machine, there are several factors that you should consider. These include:- Size: The size of the machine should be appropriate for the size of the granite you are working with.

- Power: The power of the machine should be sufficient to handle the job at hand.

- Features: Different models offer different features such as automatic functions, water-cooling, and dust collection systems. Consider the features that are most important to you.

- Cost: Granite cutting machines can vary in price depending on the features and capabilities. Choose a machine that fits within your budget but does not skimp on essential features you need for your work.

Cautions When Operating a Granite Cutting Machine

While a granite cutting machine is an efficient and powerful tool, it is essential to operate it safely. Here are some cautions to be aware of when using a granite cutting machine:- Always wear appropriate protective gear, including eye and ear protection, a dust mask, and cut-resistant gloves.

- Ensure that the blade is sharp and properly aligned before use.

- Work in a well-ventilated area, and use a dust collection system to minimize the amount of granite dust that is created during cutting.

- Do not put your hands near the blade while it is spinning, and avoid standing in the machine's path while it is in use.

- Avoid cutting granite that is wet or has loose particles as this may cause damage to the blade or machine, and increase the risk of accidents.

Conclusion

A granite cutting machine is an essential tool for professionals who deal with granite cutting. It provides efficiency, speed, and precision in cutting granite to any required size or shape. When selecting a granite cutting machine, consider factors such as size, power, features and cost. Ultimately, always prioritize safety and ensure that you take the proper precautions when operating the machine.

A granite cutting machine is an essential tool for professionals who deal with granite cutting. It provides efficiency, speed, and precision in cutting granite to any required size or shape. When selecting a granite cutting machine, consider factors such as size, power, features and cost. Ultimately, always prioritize safety and ensure that you take the proper precautions when operating the machine. Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]