Lapidary Wire Saw

Lapidary Wire Saw: A Comprehensive Guide

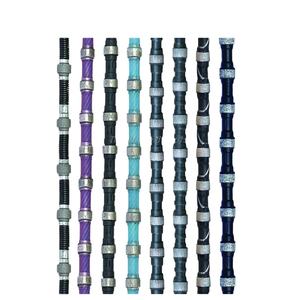

Lapidary wire saws are an essential tool for cutting and slicing gemstones and other hard materials. These saws consist of a thin metal wire embedded with diamond grit and are used to cut through rocks, crystals, and other hard materials with precision and ease. In this comprehensive guide, we will explore the uses, types, and benefits of lapidary wire saws.What is a Lapidary Wire Saw?

A lapidary wire saw is a cutting tool that is used for precise and intricate cuts on gemstones and other hard materials. The saw uses a thin metal wire with diamond grit or other hard abrasive particles embedded in it that rotates at a high speed to cut through the material. This type of saw is mainly used in the lapidary industry but can also be used by geologists, archaeologists, and others who work with hard materials.Types of Lapidary Wire Saws

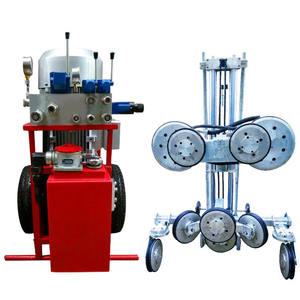

There are two main types of lapidary wire saws: continuous and oscillating. Continuous saws use a single, continuous wire that rotates around two pulleys, while oscillating saws use a reciprocating motion to move the wire back and forth through the material being cut. Continuous saws are typically used for larger, more complex cuts, while oscillating saws are ideal for smaller, more detailed cuts.

Uses of a Lapidary Wire Saw

Lapidary wire saws are primarily used for cutting and slicing gemstones, rocks, crystals, and other hard materials. They are popular tools in the jewelry industry for creating intricate designs and cutting stones for setting in jewelry. Additionally, they can be used for geological research and excavation, as well as in the construction industry for cutting building materials such as concrete and brick.Benefits of Using a Lapidary Wire Saw

One of the main benefits of using a lapidary wire saw is its precision cutting. The diamond grit embedded in the wire allows for clean, precise cuts with minimal waste. Additionally, the thin wire allows for intricate designs and cuts that may not be possible with other cutting tools. Lapidary wire saws are also relatively quiet and produce less dust than other cutting tools such as diamond saws.

One of the main benefits of using a lapidary wire saw is its precision cutting. The diamond grit embedded in the wire allows for clean, precise cuts with minimal waste. Additionally, the thin wire allows for intricate designs and cuts that may not be possible with other cutting tools. Lapidary wire saws are also relatively quiet and produce less dust than other cutting tools such as diamond saws.

Maintenance and Safety

To ensure the longevity and effectiveness of your lapidary wire saw, it is crucial to properly maintain and care for it. Regular cleaning and lubrication can help prevent the wire from breaking or becoming dull, which can result in injuries and inferior cuts. Additionally, wearing appropriate safety gear such as gloves and eye protection can protect against injuries and dust inhalation.

To ensure the longevity and effectiveness of your lapidary wire saw, it is crucial to properly maintain and care for it. Regular cleaning and lubrication can help prevent the wire from breaking or becoming dull, which can result in injuries and inferior cuts. Additionally, wearing appropriate safety gear such as gloves and eye protection can protect against injuries and dust inhalation.

Conclusion

Lapidary wire saws are essential tools for cutting and slicing gemstones and other hard materials with precision and ease. Choosing the right type of saw for your needs and following proper maintenance and safety procedures can result in beautiful and high-quality cuts.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]