Grinding Cut Off Wheels

Grinding Cut Off Wheels: Everything You Need to Know

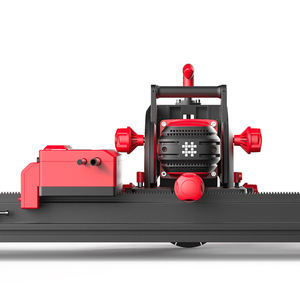

Grinding cut off wheels are a type of abrasive disc that is used for cutting, grinding, and polishing. They are an essential tool for anyone who works with metal or other materials that need to be shaped or smoothed. In this article, we will cover everything you need to know about grinding cut off wheels, from their different types to their proper usage.What Are Grinding Cut Off Wheels and How Do They Work?

Grinding cut off wheels are made of abrasive materials that are capable of grinding, cutting, and polishing different types of materials. They have a hard outer layer that is designed to withstand high speeds and pressures, while the inner core is designed to provide support and flexibility. When the cutting edge of the wheel comes in contact with the material being cut, it removes small amounts of the material until the desired shape is achieved.

Types of Grinding Cut Off Wheels

There are several different types of grinding cut off wheels available, each designed for specific applications. Some of the most common types of grinding cut off wheels include:- High-Speed Cut Off Wheels: Designed for cutting hard materials like steel and stainless steel at high speeds.

- Masonry Cut Off Wheels: Ideal for cutting bricks, concrete, and other masonry materials.

- Aluminum Cut Off Wheels: Designed for cutting soft metals like aluminum and brass.

- Diamond Cut Off Wheels: Used for cutting and grinding hard materials like glass, ceramics, and gemstones.

Proper Usage of Grinding Cut Off Wheels

To ensure the maximum lifespan and efficiency of your grinding cut off wheels, it is essential to use them properly. Some tips to keep in mind while using grinding cut off wheels include:- Wear Safety Gear: Always wear safety gear like gloves, goggles, and earplugs while using grinding cut off wheels.

- Choose the Right Wheel: Use the right grinding cut off wheel for the material you are cutting.

- Inspect the Wheel: Always inspect the wheel for any cracks or damage before use.

- Mount the Wheel Correctly: Ensure that the grinding cut off wheel is mounted correctly and securely on the machine.

- Feed the Material Slowly: Feed the material being cut into the wheel slowly and steadily to avoid damaging the wheel or the material.

- Avoid Overheating: Avoid overheating the wheel by maintaining a constant speed and pressure while cutting.

Storing Grinding Cut Off Wheels

Proper storage of grinding cut off wheels is essential to prevent damage and ensure their longevity. Some tips to keep in mind while storing grinding cut off wheels include:- Store in a Dry Area: Store grinding cut off wheels in a dry area to prevent moisture from causing damage.

- Separate Different Types: Store different types of grinding cut off wheels separately to avoid confusion and damage.

- Avoid Stacking: Do not stack grinding cut off wheels on top of each other, as this can cause damage to the wheels.

- Use Protective Coverings: Use protective coverings to protect the grinding cut off wheels from dust, debris, and other damage.

When to Replace Grinding Cut Off Wheels

Grinding cut off wheels wear out over time due to extended usage and wear and tear. It is essential to replace them regularly to ensure efficient and safe work. Signs that grinding cut off wheels need replacement include:- Worn or Damaged Edge: If the edge of the grinding cut off wheel is worn, chipped, or damaged, it needs replacement.

- Reduced Cutting Efficiency: If the grinding cut off wheel takes longer than usual to cut through materials, it needs replacement.

- Excessive Heat: If the grinding cut off wheel overheats quickly during use, it needs replacement.

Conclusion

Grinding cut off wheels are an essential tool for anyone who works with metal or other materials that need to be shaped, smoothed, or cut. With proper usage and maintenance, grinding cut off wheels can last longer and provide efficient and safe work. It is essential to choose the right type of grinding cut off wheel for the material being cut and replace them regularly to ensure maximum efficiency and safety.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]