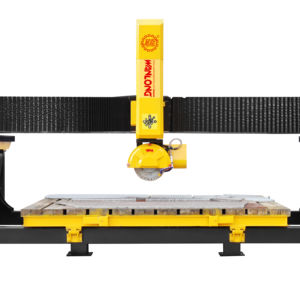

Gangsaw Machine

Gang saw Machine: The Ultimate Sawing Solution for Stone Cutting Industry

In the stone cutting industry, gang saw machines are highly advanced and innovative stone cutting machines that are highly effective and efficient. They are designed to cut large blocks of stones into slabs of preferred sizes, which can then be used in various construction purposes. The gang saw machine has become the ultimate solution for enhancing the productivity and efficiency of stone cutting industries worldwide. In this article, we will delve into the details of the gang saw machine, its features and benefits.What is a Gang saw Machine?

A gang saw machine is a highly advanced and innovative machine specifically designed for cutting blocks of stones into slabs. It uses multiple blades arranged side by side to cut stone blocks into slabs, hence the name "Gang Saw." The machine is capable of producing multiple slabs at the same time, and the blades are lubricated with water or oil to ensure a smooth cutting process.

How does a Gang saw Machine work?

The gang saw machine is composed of a massive steel frame that supports the blades, which are reciprocating back and forth. The stone block is placed on the machine bed, which is made of sawn, ground or polished steel. The blades are set into motion, slicing the stone block in a back-and-forth motion, creating multiple slabs at once. The cutting process is smooth, accurate and precise. The machine can be programmed to cut blocks of specific sizes and thicknesses, ensuring optimal use of raw material.Features of Gang saw Machine

Gang saw machines come in a variety of sizes and have different features, but some of the standard features include:

Gang saw machines come in a variety of sizes and have different features, but some of the standard features include:

- Multiple blades for efficient cutting;

- Mechanical pressure to ensure consistent slicing;

- Water or oil cooling for lubrication;

- Highly accurate cutting;

- Easy blade replacement;

- Large cutting capacity;

Benefits of using a Gang saw Machine

The benefits of using a gang saw machine cannot be overstated. They include:- Increased productivity;

- Reduced labor costs;

- Optimal utilization of raw materials;

- A wide range of cutting sizes and thicknesses;

- Precision cutting;

- Reduced waste and improved efficiency;

Types of Gang saw Machines

There are various types of gang saw machines available, each designed for specific purposes:

There are various types of gang saw machines available, each designed for specific purposes:

- Marble Gang Saw Machines: used for cutting marble blocks into slabs;

- Granite Gang Saw Machines: used for cutting granite blocks into slabs;

- Travertine Gang Saw Machines: used for cutting travertine blocks into slabs;

- Sandstone Gang Saw Machines: used for cutting sandstone blocks into slabs.

Maintenance of Gang saw Machine

Maintenance of gang saw machines is crucial. Regular maintenance ensures that the machine is functioning at its best and that it has a long lifespan. Proper cleaning, lubrication, and blade replacement should be carried out regularly. The machine should also undergo regular servicing by qualified personnel.Conclusion

The gang saw machine is a revolutionary invention in the stone cutting industry. It has greatly enhanced productivity, reduced labor costs, and above all, ensured optimal utilization of raw materials. The machine is designed to cut large stone blocks into multiple slabs at once, ensuring accuracy, precision, and efficiency. As technology advances, gang saw machines will continue to play an essential role in the stone cutting industry.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]