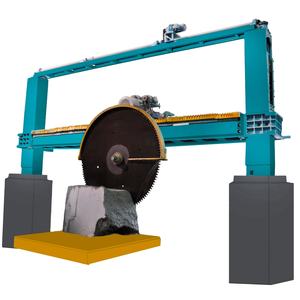

Bridge Saw Cutting Machine

Bridge Saw Cutting Machine: The Ultimate Tool for Precise Stone Cutting

If you are in the business of manufacturing or installation of marble, granite, or any other stone, then you know the importance of having precise and accurate cuts. With a bridge saw cutting machine, you can achieve just that with minimal effort. This modern technology has revolutionized the stone industry, making it easier to cut and shape even the toughest stones with accuracy and consistency.What is a Bridge Saw Cutting Machine?

A bridge saw is a large cutting machine used to cut stones with accuracy and precision. The machine consists of a diamond-coated blade that is mounted on a bridge that moves across the worktable. The bridge saw can make precise straight or curved cuts in stones of various sizes and thicknesses, making it a versatile tool for cutting and shaping workpieces.Types of Bridge Saw Cutting Machines:

There are typically three types of bridge saws:Manual Bridge Saw:

The manual bridge saw is operated manually by an operator to make cuts in the stone. The operator controls the movement of the bridge, and the blade manually. It is a cost-effective option that is perfect for small stone cutting and fabrication shops.

Semi-Automatic Bridge Saw:

The semi-automatic bridge saw is a hybrid between manual and fully automatic machines. It requires some manual operation by an operator but is also equipped with semi-automatic features that make the cutting process easier and more efficient.Fully-Automatic Bridge Saw:

The fully automatic bridge saw is designed to work without human intervention. It uses modern technology, such as programmable logic control (PLC), to make precise cuts in stones. This type of bridge saw is ideal for large-scale production and manufacturing.

The fully automatic bridge saw is designed to work without human intervention. It uses modern technology, such as programmable logic control (PLC), to make precise cuts in stones. This type of bridge saw is ideal for large-scale production and manufacturing.

How Does a Bridge Saw Cutting Machine Work?

The bridge saw cutting machine uses a diamond-coated blade to cut stones. The blade is powered by an electric motor that rotates at a high speed, allowing it to cut through tough materials. The stone is secured on the worktable, and the blade moves across the worktable to make the desired cuts. The bridge saw comes with a built-in water pump that cools the blade and reduces the amount of dust generated during the cutting process. This means that the saw can make clean and precise cuts, making it the best tool for stone cutting and shaping.

Benefits of Using a Bridge Saw Cutting Machine:

Using a bridge saw cutting machine has numerous advantages. Here are some of them:Precision and Accuracy:

Bridge saws are designed to make precise and accurate cuts, leaving a clean and smooth finish on the stone workpiece.Efficiency:

The bridge saw can cut and shape multiple stones quickly, improving productivity and efficiency.

The bridge saw can cut and shape multiple stones quickly, improving productivity and efficiency.

Versatility:

Bridge saws can cut stones of various sizes and thicknesses, making it a versatile tool for stone cutting and fabrication.Reduced Labor Costs:

Using a bridge saw eliminates the need for manual labor, which reduces labor costs and increases profit margins.

Conclusion:

In conclusion, a bridge saw cutting machine is an essential tool for the stone industry. The machine makes it easier to cut and shape even the toughest stones with accuracy and consistency. With the different types of bridge saws available, you can choose the best tool that suits your stone cutting and fabrication needs. Whether you are operating a small shop or a large-scale manufacturing business, investing in a bridge saw cutting machine will undoubtedly improve your productivity and increase your profit margins.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]