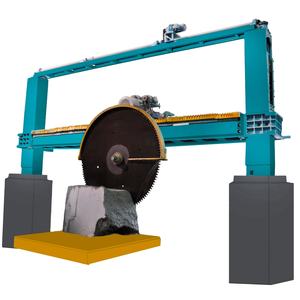

Automatic Bridge Saw

Automatic Bridge Saw: An Innovative Solution for Stone Cutting

If you’re in the business of cutting stones and conducting masonry work, you would know the importance of a reliable and efficient cutting tool. The manual effort involved in the cutting process can put a strain on the workforce, and often yield inaccurate results. With the advent of technology, the industry has witnessed a transformation with the introduction of Automatic Bridge Saws. This article describes the innovative solution of an automatic bridge saw, how it works, and its benefits.

What is an Automatic Bridge Saw?

An Automatic Bridge Saw is a cutting tool that uses computer numerical control (CNC) technology to cut natural and engineered stones into precise shapes and sizes. It is a computerized machine that cuts and sizes stones by translating the 2D designs into automated movements, with little manual intervention. The machine features an overhead gantry that holds the saw blade and moves it back and forth along the x and y-axis. The machine is programmed to operate with precision and accuracy, ensuring accuracy in every cut.How Does an Automatic Bridge Saw Work?

The machine operates on CNC technology, which controls the blade’s movement in three axes: x, y, and z. There is a computerized control panel where the operator can input the cutting parameters, such as cutting speed, depth, and the cutting angle. Once the parameters are inputted, the machine begins cutting the stone with automatic movements. The machine’s overhead gantry controls the movement of the saw blade, which features a diamond-tipped blade to cut through the materials.

Benefits of an Automatic Bridge Saw

Efficiency

The Automatic Bridge Saw operates with efficiency and speed, completing tasks faster than a manual laborer. The machine can work continuously without the need for breaks, resulting in higher productivity for the business.Accuracy

The precision and accuracy of the machine are unmatched, delivering higher-quality cuts without deviations. The machine’s computerized technology ensures that each cut is perfectly aligned with the 2D design, resulting in better-finished products.Versatility

An Automatic Bridge Saw can cut a wide range of stones, including granite, marble, limestone, and sandstone, among others. The machine’s adaptability makes it a versatile tool for various masonry jobs.Safety

A manual saw can pose health risks to the worker, such as respiratory problems caused by inhaling the dust. The Automatic Bridge Saw offers a safer option as it reduces the amount of dust produced during the cutting process, keeping the workspace clean and safe.

A manual saw can pose health risks to the worker, such as respiratory problems caused by inhaling the dust. The Automatic Bridge Saw offers a safer option as it reduces the amount of dust produced during the cutting process, keeping the workspace clean and safe.

Applications of an Automatic Bridge Saw

The Automatic Bridge Saw is an invaluable asset in the masonry industry, delivering reliable and precise cutting solutions for various applications. The machine is used in the following applications:Countertops and Vanity Tops

Countertops and vanity tops require precise cuts to fit the dimensions of the kitchen or bathroom area. The Automatic Bridge Saw makes this possible by delivering quality and accurate cuts.

Countertops and vanity tops require precise cuts to fit the dimensions of the kitchen or bathroom area. The Automatic Bridge Saw makes this possible by delivering quality and accurate cuts.

Architectural Elements

The Automatic Bridge Saw is ideal for cutting stones into various shapes and sizes needed for architectural elements such as columns, capitals, and cornice moldings.

The Automatic Bridge Saw is ideal for cutting stones into various shapes and sizes needed for architectural elements such as columns, capitals, and cornice moldings.

Monuments and Memorials

The machine’s ability to cut intricate designs and shapes make it ideal for creating memorials and monuments. Custom designs and inscriptions can be easily realized with the Automatic Bridge Saw.Conclusion

The Automatic Bridge Saw has revolutionized the stone cutting industry, delivering reliable and precise cutting solutions for various applications. The machine’s efficiency, accuracy, versatility, and safety make it a valuable asset to any masonry business, reducing manual labor and providing higher-quality finished products.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]