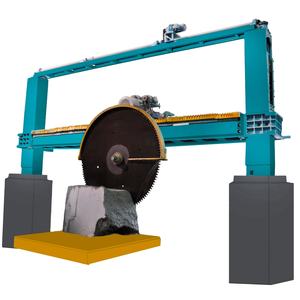

5 Axis Cnc Bridge Saw

5 Axis CNC Bridge Saw – The Innovative Stone Cutting Machine

In the world of stone cutting and fabrication, 5 axis CNC bridge saws are the new innovative machines that are emerging as game changers. These powerful machines can cut and shape stones with extreme precision, perfect for countertops, flooring, facades, and other applications.The Basics of 5 Axis CNC Bridge Saws

A 5 axis CNC bridge saw is a computer-controlled machine that uses diamond blades and water to cut through stones. It is equipped with advanced software that simplifies the process of cutting and can handle heavy-duty tasks that would be impossible to accomplish by hand. With five axes of movement, these machines can cut stones in any direction, allowing for more intricate shapes and designs.The Advantages of Using 5 Axis CNC Bridge Saws

There are several advantages to using a 5 axis CNC bridge saw. Firstly, it is faster and more efficient than manual methods, saving time and labor costs. Secondly, it is more accurate and produces flawless results with less wastage. Thirdly, it can handle a wider range of stone types and thicknesses. Finally, it reduces the risk of worker injuries and accidents that may occur during manual cutting.Applications of 5 Axis CNC Bridge Saws

These machines are versatile and can be used for a variety of applications. One common use is for creating countertops in kitchens, bathrooms, and other areas. The precision of cutting allows for exact measurements and customization of the edge profiles, allowing for a seamless fit. Another application is in the creation of monuments and memorials, where intricate designs and inscriptions can be carved into the stone. These machines are also used for flooring, wall cladding, and facades.

Key Features of 5 Axis CNC Bridge Saws

To achieve optimal performance, 5 axis CNC bridge saws have several key features that make them stand out. Firstly, they have a robust structure with high-grade materials that ensure durability and stability. Secondly, they have a user-friendly software interface that simplifies the process of cutting and allows custom settings. Thirdly, they have advanced cooling systems that ensure the blades stay sharp and last longer. Finally, they have advanced dust-collection systems that keep the work environment clean and safe.

To achieve optimal performance, 5 axis CNC bridge saws have several key features that make them stand out. Firstly, they have a robust structure with high-grade materials that ensure durability and stability. Secondly, they have a user-friendly software interface that simplifies the process of cutting and allows custom settings. Thirdly, they have advanced cooling systems that ensure the blades stay sharp and last longer. Finally, they have advanced dust-collection systems that keep the work environment clean and safe.

Maintenance and Safety Tips for 5 Axis CNC Bridge Saws

To ensure the longevity and proper functioning of a 5 axis CNC bridge saw, it is essential to follow proper maintenance procedures. This includes regular cleaning, inspection, and oiling of moving parts. Additionally, the blades must be checked regularly for wear and tear and replaced when necessary. Safety is also paramount when using these machines. Operators should wear personal protective equipment such as goggles, gloves, and dust masks. They should also be familiar with the software and emergency shut-off procedures.

To ensure the longevity and proper functioning of a 5 axis CNC bridge saw, it is essential to follow proper maintenance procedures. This includes regular cleaning, inspection, and oiling of moving parts. Additionally, the blades must be checked regularly for wear and tear and replaced when necessary. Safety is also paramount when using these machines. Operators should wear personal protective equipment such as goggles, gloves, and dust masks. They should also be familiar with the software and emergency shut-off procedures.

Conclusion

In conclusion, a 5 axis CNC bridge saw is an innovative machine that is changing the game in the world of stone cutting and fabrication. Its advanced technology, high efficiency, and precision make it a top choice for a range of applications. Furthermore, proper maintenance and safety measures should always be followed to ensure optimal performance and safety.Request for Quotation

[contact-form-7 id="59" title="Contact form 1"]